Hi, I’m Leo Liang. Here at Sinriya, in the downtown area of Foshan, my days are surrounded by the hum of equipment and the sharp, metallic scent of aluminum. I’ve worked for years now in the world of B2B building materials, but I’m most excited about the life-enhancing potential of aluminum decorative trim. As I do and thanks to my blog, Sinriya.com, I’ve also been able to work with designers and architects to help them achieve their vision with a material that all too often is the odd man out.

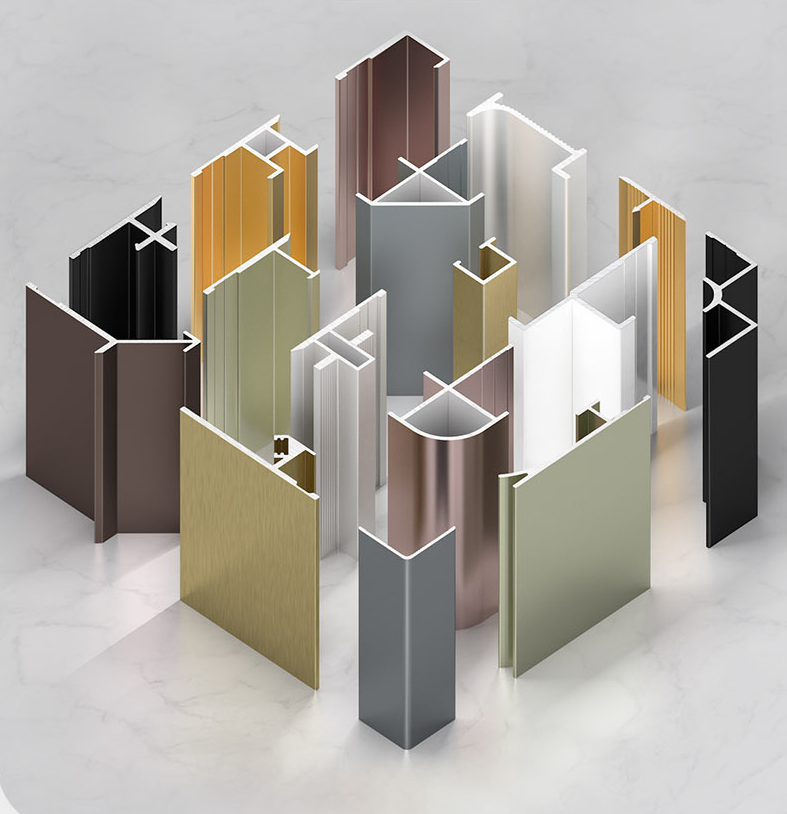

Aluminum trim is to some just a boring finishing strip. But I’ve seen it redefine spaces, create clean, modern lines where there were none before, and solve functional problems that wood or PVC can’t even begin to. It’s a product whose narrative is one of design and durability. In this post, I’d like to pull back the curtain and share with you—from my own experience—why aluminum trim is so much more than an afterthought. We’ll dive into the particular alloys, the type of finish that gives it sizzle, and the precise applications where it can make a project go from just okay to amazing. This is the kind of technical, practical information that our B2B clients, from architects to interior designers, come to us for.

What Exactly Are We Talking About when we say “Aluminum Trim”?

When designers initially come to me, they consider aluminum trim as just an “edge.” Oh, it’s so much more. What we’re actually working with is extruded aluminum profiles. Think of a highly engineered process in which an aluminum solid billet is heated and pushed through a specially designed die. The outcome is an absolutely uniformed profile, piece after piece, with precision beyond imagination. This makes it possible for us to produce complicated forms that would otherwise be impossible or impossibly costly with other materials.

It’s aluminum’s inherent properties that make it such a high achiever when it comes to design and building. It’s also extremely lightweight, so it’s a much lighter load for building frames and cheaper, less labor-intensive to deliver and put up. It’s also very corrosion-resistant and long-lasting, unlike warping or rotting wood, or rusting steel. And most importantly in the world today, maybe, it’s a sustainability star. Aluminum can be recycled over and over again without degradation of properties, which is music to the ears of any green building practitioner or LEED certification-seeker. I remember one project with a green design architectural firm; their specification of recycled aluminum trim actually garnered them LEED points, a win-win for the environment and for the prestige of the project.

Not All Aluminum is Created Equal: How to Choose the Right Alloy

Perhaps the most common question I get from professional customers is what type of aluminum we use. That is where the technical data comes in. For architectural and decorative applications, the default option is almost always 6063 aluminum alloy. The silicon- and magnesium-based alloy is renowned for its superior finish characteristics and improved corrosion resistance. But its hidden strength is its extrudability—it allows for the formation of intricate, complex shapes with very smooth surfaces, perfect for exterior architectural profiles like window frames, door frames, and decorative trim.

You’ll typically see this alloy referred to as 6063-T5. The “T5” refers to the temper designation, and that’s significant. It tells you that the aluminum has been artificially aged in a furnace and cooled from the extruding temperature. It makes it stronger and a lot harder, so that the final product will be able to withstand the strains of a very busy environment. We utilize 6063-T5 for most of our profiles at Sinriya because it offers the perfect compromise that architects and designers need: it’s hard enough to be strong, but soft enough to shape into exquisite forms, with a surface pure enough to finish.

How Do You Achieve That Perfect Look? A Close-Up on Finishes

Extruded raw aluminum is just the starting point; it’s the finish that breathes life into it and makes it endure. In my line of work, the two most popular and useful finishing techniques used are powder coating and anodizing, and designers frequently ask me to compare and contrast.

Anodizing is an electrochemical process where the trim is dipped into an acid bath and an electric current is run through it. It doesn’t deposit a coating over the aluminum but instead increases the naturally occurring protective oxide layer, so the finish is part of the metal itself. This creates a very tough finish that resists chipping, peeling, and corrosion. It provides that deep rich metallic look which is hard to achieve, typically in clear (matte silver), bronze, or black finishes. It’s an excellent choice for high-wear items or if you wish to highlight the very metallic nature of the material.

Powder Coating, on the other hand, is electrostatic spraying of a dry powder onto the aluminum and heating it in an oven to form a hard protective skin. The only true advantage here is the nearly unlimited color palette. We can color to nearly any brand color or design scheme, and it comes in many different varying textures such as matte, gloss, or satin. While highly durable, a powder coat is a surface coating, and it can be more prone to deep scratches or chipping than an anodized finish. My recommendation to clients is typically the following: for ultimate durability and a genuine metallic look, anodized is the way to go. When a project demands custom color matching and design flexibility, powder coating is the way to go.

Where Can You Place Aluminum Trim to Make a Room Truly Shine?

Here is where the imagination kicks in. The pliability of aluminum profiles is so versatile that they can be used in so many applications to solve issues of beauty and function. I have seen our Sinriya products being applied in applications that are just genius and gorgeous.

The principal application scenarios are:

Tile Trim: A classic. Round-edge, square-edge, and L-shape aluminum profiles guard exposed tile edges in bathrooms and kitchens against chipping. It also provides a neat, professional finish, concealing the unglazed edge of the tile.

Stair Nosing: This is a significant application for safety and durability. Aluminum stair nosing provides a hard-wearing, typically anti-slip, edge to stair treads, providing them with a barrier against wear and tear on high-traffic domestic or commercial property. Many profiles have PVC or rubber inserts to provide improved grip.

Skirting Boards: I’m seeing a huge trend towards aluminum skirting boards as a modern, minimalist alternative to traditional wood. They are completely waterproof, pest-proof, and won’t warp or crack, making them ideal for any environment. A sleek, brushed aluminum skirting board can create a stunning transition between wall and floor.

Wall & Ceiling Transitions: Architects like to use aluminum trim to create purposeful, crisp details. Minimal profiles can be used to create shadow gaps between panels or where a wall meets a ceiling, providing a touch of sophisticated detail. They are also effective as transition strips between different flooring types, i.e., tile and wood.

What are the Standard Sizes and Shapes I Should Be Familiar With?

Although personalization is one of the best advantages, there are standard sizes which are helpful to know for designers and architects for planning purposes. For decorative purposes in most cases, the profile thickness of the wall is a helpful measure of durability and quality. Opt for 1mm to 2mm thick profiles.

For applications like tile trim, the height is designed to correspond to the standard tile thicknesses. You’ll see 8mm, 10mm, and 12.5mm heights. This provides a flush, watertight finish to the tile’s surface. Standard lengths are 2.5 meters (around 8 feet) or 3 meters (around 10 feet) in order to minimize joints on long runs.

But where aluminum’s strength really lies is in the ability to customize. We at Sinriya regularly work with design firms to create brand new extrusion dies for bespoke profiles. One hotel project I consulted on was a unique skirting board profile that would contain an LED light strip discreetly, to supply low-level ambient illumination. You simply cannot achieve that with standard off-the-shelf PVC or timber trim. It’s this capacity for customization of extrusion that has opened the door to a universe of possibility for B2B clientele.

Why Aluminum as Opposed to Conventional Choices like Wood or PVC?

This is a question I’m posed almost daily, and the advantages of aluminum are apparent and convincing.

Versus Wood: Water is the biggest variable. Cut wood, especially in kitchens, bathrooms, or even mopping floors, will take on water, swell, buckle, and create mold or rot. Aluminum is water-resistant. It’s also pest-proof and termite-proof, big concerns in most climates.

Versus PVC/Plastic: While PVC is waterproof, it lacks the same high-end look and rigidity of aluminum. It will be brittle with time, chip upon impact, and have the inclination to appear what it is: plastic. Aluminum delivers a much more high-end, resilient, and architecturally relevant feel. Additionally, the recyclability of aluminum renders it a far greener choice than plastic.

Versus Stainless Steel: The other high-end option is stainless steel, but aluminum is considerably lighter and usually less costly. Most importantly, aluminum is a considerably easier metal to cut and work with in the field, lowering installation labor costs and installation time. With new finishes like anodizing, aluminum has equal corrosion resistance for the majority of interior and architectural applications.

In my experience, choosing aluminum is about choosing long-term performance and peace of mind. I’ve seen too many beautiful projects destroyed by rotting wood trim in wet areas. Professionals choose aluminum for a very hard and long-lasting finish.

What are the Major Industry Trends Shaping the Future of Aluminum Trim?

As a practitioner in this field, I’m always looking out for what’s next. What I’m seeing is encouraging because it goes on to wed appearance with even more functionality. The world is becoming more integrated and less obtrusive.

A trend that’s dominating is minimalism and the use of shadow gaps. More architects are using very thin, typically black, recessed profiles to create the illusion of crisp, clean edges and a sense of depth between surfaces. Built-in LED lighting is another massive area of expansion. The profiles are actually being designed to double as housings for LED strips, enabling designers to wash walls with light, illuminate staircases, or create ambient light effects from skirting boards, all in a single, integrated system. Finish and color customization continue to become more popular as designers move away from generic silver and attempt to color match trim with powder coating. Finally, sustainability is no longer a second thought; it’s foremost in mind. Aluminum is a favorite for sustainable projects due to high recycled content and unlimited recyclability.

How Can I Ensure a Perfect, Professional Installation?

A great material is only as good as the installation. A single bad cut or incorrect adhesive will render the completed product unusable. Based on my years of troubleshooting and consulting with installers, here are my most critical tips.

Then the correct cutting tool is used. One needs a miter saw with a carbide-tipped blade designed for cutting non-ferrous metal. Aluminum cut with a wood blade will result in a rough, burred edge. Be patient and allow the blade to do the work for a clean cut.

Second, to hold it in place, an appropriate construction adhesive or tile mortar is typically used. For wall-against installations, the application of a continuous bead of adhesive is typically sufficient. Some systems also employ mounting clips for a mechanical grasp.

Third, mind the corners. To look professional, mitered 45-degree corners are standard for creating neat outside and inside corners. This is where accuracy is most important. Finally, leave the protective plastic sheet in place over the trim for as much of the installation as possible. This will defend the finished surface against scratches, adhesives, or grout. Its removal should be included in one of the final stages of the project.

It’s the details that make the design, and in contemporary design, aluminum trim is one of the greatest details in your arsenal.

Future Directions for Content

Take the “Problem-Solving” & “How-To” Content to a Deeper Level: Produce tutorials titled “How to Design Custom LED-Integrated Skirting for a Seamless Appearance” as well as “Aluminum Trim Installation Mistakes and How to Repair Them.”

Enhance “Inspiration” & “Trends” Content: Develop style guides like “The Modernist’s Handbook: Creating Contrast and Definition Using Black Aluminum Trim” or “Biophilic Design: Blending Natural Wood Tones with Bronze and Champagne Aluminum Finishes.”

Highlight “Expertise” & “Authority” to B2B Buyers: Release technical whitepapers like “A Specifier’s Guide to Aluminum Alloys: 6063 vs. 6061 for Architectural Applications” or “The Anodizing Thickness Factor in Long-Term Durability for Commercial Projects.”

Build “Brand Story” & “Trust”: Post behind-the-scenes content such as “From Billet to Building: The Life of a Sinriya Aluminum Profile” or “Meet the Engineer: The Brain Behind Our New Profile Designs.”

Foster “Interaction” & “User-Generated Content”: Sponsor a professional contest for work done with Sinriya trim, and feature the winners on our blog and social media.

References

American Douglas Metals (ADM). (2024, January 18). Aluminum In Construction: The Future Of Sustainable Building. https://www.admsmetals.com/blog/post/aluminum-in-construction-the-future-of-sustainable-building

Eagle Mouldings. (n.d.). Aluminum Trim Installation Instructions. https://www.eaglemouldings.com/installation-instructions.html

iQubx. (2017, June 8). Aluminium a green building material. https://www.iqubx.com/aluminium-a-green-building-material/

Focus Keywords

Aluminum Trim

Architectural Aluminum Profiles

6063-T5 Aluminum

Anodized Aluminum Trim

Aluminum Skirting Board